Description

Technical parameter of the injector calibration machine:

- Output power: 11 KW

- Rotation speed controlling: inverter

- Power supply: 380V 50/60HZ

- Rail pressure:0-2700bar ( as requests)

- Rail pressure precision tolerance: ±5 Bar

- Oil pressure regulation range:0-250bar

- Diesel fuel pressure regulation range:0-0.6 Bar

- Fuel tank capacity : 20/40 liters

- Fuel temperature controlling : 40±2℃

- Fuel tank filtration: less than 5μmfor 20L , less than 3μ for 40L

- Pulse width:100-3000μs

- Machine size: 1500×950×1700 mm

- Weight:500kg

Injector test applications

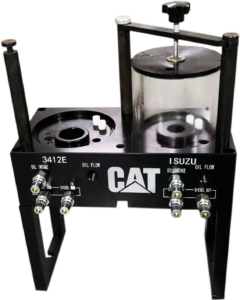

HEUI injector test adaptors:

Hardware advantage of this common rail diesel injector test bench

- Equipped with Boschgenuine CP3pump.

- Industrial Air Conditioning Refrigeration

- Flow sensor of the injector bench : imported flow sensor

- Automatically testing leakage of diesel fuel and oil.

- Testing oil can be heating automatic

- Diesel fuel system and oil working system are separated.

- Cleaning the common rail injectors by high pressure flushing.

- Frequencyinverter equipped to achieve testing function under different speed conditions

- The diesel injector testing machine has the Short-circuit protection, ground protection, overpressure protection during the testing.

- The precision filteris used before fuel comes to flow sensor, can effectively keep the sensor clean and extend the flow sensor usage life.

Software advantage of the CRDI injector testing machine

- Multi-language applys on this diesel injector calibration machine

- Software advantage: Intelligent algorithm isused to automatically calibrate the fuel quantity of the new injector, and generate test plan after calibration.

- Automatic measurement of the common rail injectors and Caterpillar HEUI injectors ( including 3126 injectors) under different working conditions, automatic analysis of measurement results, and generation of reports

- User can customize parameters such as rail pressure, pulse width, and fuel injectiontime when using this common rail injector test stand.

- Data backup, system software and function upgrade by romote control.

- Testing data same as Bosch, Denso, Delphi original data, accuracy can reach to be the genuine data.

- Real-time display of fuel injectionand back-flow curve, automatic testing the fuel quantity of all working conditions, automatic generation of report after

- Industrial computer real-time control, windows operating system, built-in display, touch screen operation.

- Full automatic operation when using the fuel injector test equipment.