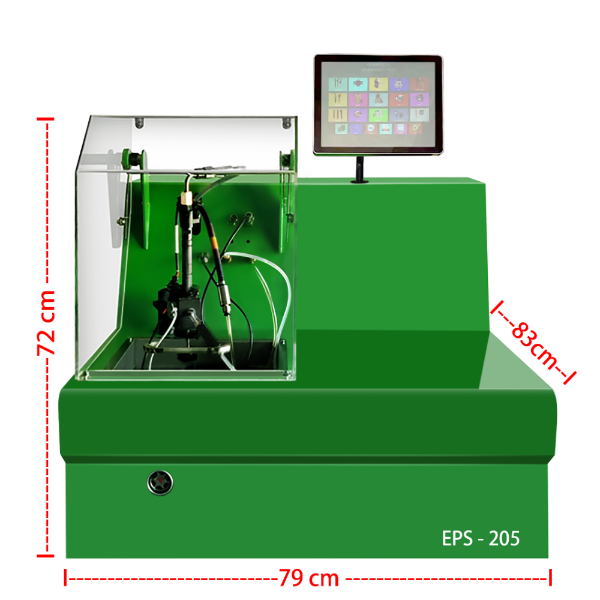

Description

CRI518 Common Rail Injector Test Bench

Model Number:CR518

Power Supply:220VAC/380VAC

Phase:Single Phase/Three Phases

Power:5.5KW

Main tank capacity:30 litres

Rail pressure test range:0-2700bar

Dimension:142x92x156cm 400kgs

Injectors Supported: Compatible with a wide range of electrically controlled injectors, including Bosch, Siemens, Caterpillar, Cummins, etc.

Test Parameters: Measures tightness, full load flow, return oil flow, idle performance, speed flow, pre-injection flow, and other performance curves. Utilizes piezoelectric sensors, eliminating the need for a separate computer board.

High-Precision Testing:Flow Sensor: Equipped with an original imported flow sensor from Germany for precise and reliable test data, closely aligned with Bosch’s professional standards.

Injector Performance Checking:

Response Time Test: Assesses the injector’s response speed.

Armature Lift Test: Evaluates the lift of the injector armature.

Solenoid Valve Testing:

Resistance Test: Measures solenoid valve resistance.

Inductance Test: Checks solenoid valve inductance.

Pulse Width Test: Tests the activation pulse width of the injector.

Pressure Test: Measures injector performance under pressure.

Additional Features:

Real-Time Data Updates: System data is updated online by the server in real time.

Optional Industrial Air-Conditioning: Available for temperature control and refrigeration.

Temperature Control: Maintains working oil temperature below 42°C during continuous 24-hour operation.

Reliability: Designed for high reliability and consistent performance year-round.

Rail Pressure Capability: Supports rail pressures up to 2700 bar.

Bosch CRIN4 Injector Testing: Compatible with 4Pin Bosch CRIN4 injectors.