Common Rail Injector Tester-Stroke Measuring Tool ( Applys For Bosch CRIN1 and CRIN2)

Common rail injector tester- stroker tester instruction manual( for first generation)

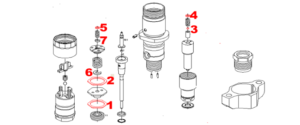

Bosch CRIN1 common rail injectors:

- Armature stroke adjusting shim

- Remaining air gap adjusting shim

- Nozzle stroke adjusting shim

- Nozzle pin valve spring force adjusting shim

- Solenoid valve spring force adjusting shim

- Circlip

- The armature total stroke adjusting circlip

- The armature total stroke of the common rail injector : (Standard values: 85-95um)

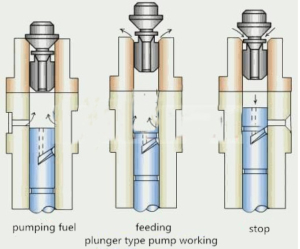

Pull down solenoid valve, remove the ball and seat, put armature parts and adjusting shim, put the small bush with opening, and screw the small bush on, fit gauge stand adaptor. amesdial and pins, fix the amesdial and ensure good amesdial sliding and amesdial shows “zero”, gently press the top of the meter axis with fingers, what it displays now is: armature total range.

- The armature stroke tester of the common rail injector: (standard value:45-50um)

Load the ball and seat properly into the small bush with an opening, screw the small bush with an opening on, and then screw on gauge stand adaptor, fit on amesdial and probe, fix the amesdial and ensure good amesdial sliding and amesdial shows “zero”, gently press the amesdial top with fingers, what it displays now is: armature lift.

- Remaining air gap of the common rail injector: (standard value:35-55um)

3.1 Remove the solenoid valve springs and shim, put armature into solenoid valve, pls do not put air gap lift shim at this time, smooth test normalized “zero”

3.2 Remove armature, put the air gap shim into do testing, what it displays now is: air gap lift.

After you displace the valve assembly of the diesel fuel injector:

Test nozzle pin valve lift, which decides nozzle pin valve shim thickness (Horsepower different of the common rail injector)

Test armature total stroke, which decides circlip thickness

Test armature stroke, which decides the hexagonal shim thickness below.

Test remaining air gap, which decides the hexagonal shim thickness above.

If VE of the common rail injector is not proper, pls debug solenoid valve of spring force adjusting shim.

If LL of the common rail injector is not proper, pls debug nozzle pin valve spring force shim.

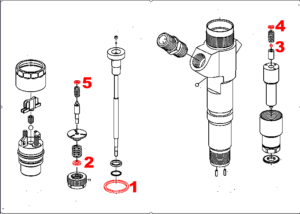

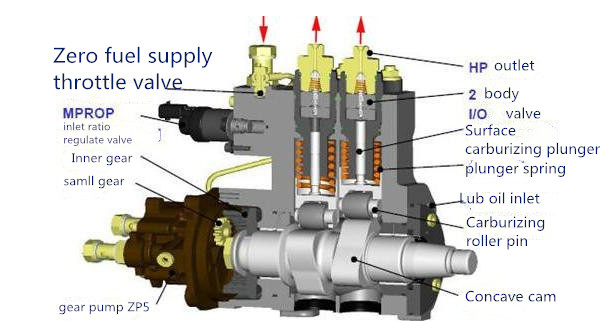

Bosch CRIN2 fuel injector tester:

1: Armature lift adjusting shim

2, Cross lift adjusting shim

3, Nozzle pin valve lift adjusting shim

4, Nozzle pin valve spring force shim

5. Solenoid valve spring force adjusting shim

- Armature stroke tester of the common rail injector (standard value: 45-50um)

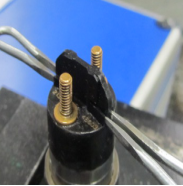

Remove solenoid valve Insulation barrier using special tool, remove the plug and remove the steel ball, remove the solenoid valve, take electromagnet spring and shim out, and then fit on solenoid valve, firstly use the probe downward pressure to check if there is a gap or not, as no clearance pls check ball valve assembly is correct or not, choose to use correct test joints & tighten the solenoid valve according to 《standard torque》, fit on gauge standard adaptor and the longest probe, push amesdial pin to ensure slide freely. Repeatedly press amesdial axis lightly after you make the amesdial shows zero, the reading now is: armature lift.

- Cross stroke tester for the common rail injector(standard value:35–50um):

Step 1: Remove the solenoid valve, remove the valve ball and seat, return spring. Fit on armature and cross lift shim, fit on amesdial & adaptor using spherical gaugehead, place on injector and recognize normalized “zero.

Step 2: Remove gauge, armature assembly and cross lift shim, fit on valve ball, ball seat, armature assembly and cross lift shims to test and confirm the reading, that is: cross stroke data.

- Common rail injector remaining air gap testing : (standard value:35–55um):

The excircle of electromagnet end face is armature clamping surface, and the excircle is higher than the inner ring surface, this height difference is the remaining air gap of the common rail diesel fuel injector, choose proper adaptor, fitted spheric gaugehead, and adjust it to show “zero” on flat surface, make it close together solenoid valve end surface, the testing data of gaugehead aiming at the inner ring surface to test is “Remaining air gap”.

- Common rail Injector tester-pin valve stroke and wear measurement:

Choose gauge stand adaptor and pin, make it show zero on flat surface, test nozzle pin valve sinking size, load spring, shims, ejector rob and maximum injection adjusting shim, use amesdial to test distance between this height and injector end face, plus nozzle pin valve sinking size, that is pin valve lift, and the size of pin valve lift is the amount of max injection, without influence to other fuel capacity.