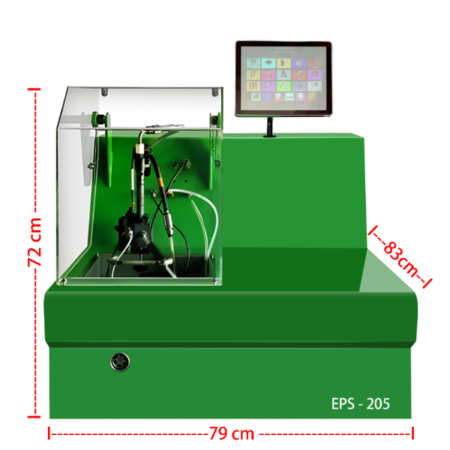

Description

8PSB Diesel Injection Pump Test Bench

| Adjustable cylinders | Out power(Kw) | RPM | Rpm pre-set | Temperature control system | Positive pressure system | negative pressure system |

| 8 | 7.5,11,15 ,18.5,22 | 0-4000 | √ | √ | √ | √ |

| Air supply | DC power supply | Internal pressure of VE pump | Oil return of VE pump | travel of tooth bar | Oil lubricate | Capability with pump type |

| √ | √ | √ | √ | (optional) | (optional) | All in- line and

rotary pump |

MINI 8PSB series diesel fuel injection test machine is design for customer’s require. This series test bench adopt high quality frequency conversing device, and it has characteristic with hi-reliability, ultra-low-noise, energy save, high output torque, perfect auto-protecting function and operate easy. It is the kind of product with high quality and good price in our business.

Main function

1.Measurement of each cylinder delivery at any speed.

2. Test point and interval angle of oil supply of injection pump.

3. Checking and adjust the mechanical governor.

4. Checking and adjusting the distributor pump.

5. .Experiment and adjusting of behavior of supercharging and compensatory device.

6. Measurement of oil return of distributing pump

7. Testing of the electromagnetic valve of distributor pump.(12V/24V)

8. Measurement of the internal pressure of distributor pump.

9. Checking of the advance angle of advance device.(on request)

10. Checking the sealing of injection pump body

11.Install tube of auto-sucking oil supply can check on oil supply pump(including VE pump).

12. Checking the travel of stroke (on request)

13. Advance angle checking

MINI 8PSB Diesel Fuel Inection Pump Test Bench Characteristics.

1. Changing frequency changing rotational speed

2. Low fall of rotational speed and high output torque

3. High measurement precision;

4. The functions of over voltage, overload and short circuit protection;

5. Ten classes Rotation speeds presetting;

6. Constant temperature controlled;

7. Ultra low noise;

8. Operating position: arbitrary side of the two work sides of the test stand;

9. Built-in air resource;