How To Choose A Common Rail Tester?

How to choose a common rail tester?

There are dozes of common rail tester manufacturers on Chinese market. Each of them promotes the quality of their common rail tester. The price of the common rail tester ranges from tens of thousands to hundreds of thousands.

Today, I will briefly explain here how to choose a suitable common rail test bench,below are some important facts for your reference, hope it will be helpful for you.

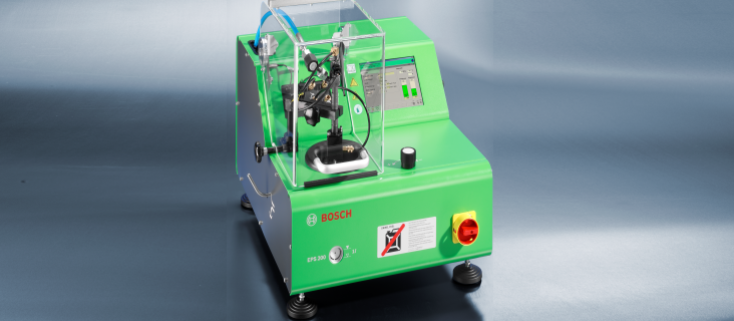

1.The weight of the common rail tester, the weight of determines its own balance and shake. Usually, the test bench with relatively low price can be obviously felt that it is shaking during the test, and the balance of the common rail tester bench is not good.

2.The power of the common rail tester, some customers need 7.5KW, some customers want 18.5KW, the standard power produced by the test bench manufacturers in China is 11KW and 15KW, the power is different, the components equipped on the test bench is different, such as universal joints ,coupling, frisbee, and the weight of these parts determines the smoothness and inertia of the speed.

3.The quality of the main parts which are on the common rail tester: fuel pump, rail, DRV, pressure sensor, control valves, must ensure that are geniune and new, such as bosch DENSO DELPHI pumps and rails are good choice, regarding these parts, i would like to say a little more, after all, it is too important for a common rail tester’s performance.

The common rail is the pressure accumulator, and the fuel pump is the source of power.

The stability of pressure and fuel temperature will directly affect the repeatability and stability of the test data.

That is to say, the performance of the rail and the common rail pump will directly affect the accuracy of the data.

But in order to confuse customers, some manufacturers will work hard on the software to keep the pressure data displayed on the test bench in a stable state, to cheat customers. At this time, you can take a mechanical pressure gauge to test whether the actual pressure and the displayed pressure on the test bench are consistent.

Or you can take a single test on the test bench with a fuel injector, single-step test and continuous test to check the repeatability and stability of the data.

Regarding the rail of the common rail tester, some manufacturers use the original Bosch rail, means rail and DRV are together( complete), but more manufacturers in order to save costs, fight with others by cutting prices , they use the common rail from Chinese market, some are dismounted from engine, and clean the appearance, and DRV (DRV also has different places to produce ), with an adaptor in the middle (I personally refer to call this as “rail combination”), such a combination of rails will be much cheaper than the original rail, but according to the test experience of the test bench manufacturers, this The rail combination can also be used to meet the test requirements. After all, most of the customers need to buy a cheaper common rail tester, but I am not a professional technician. I don’t know how much is the difference of the influence in the performance of the test bench by using the this two types rails on the common rail test bench,

Regarding the fuel pump, the pump of CP3 is generally equipped on the common rail test bench, and the pump of the CP1 is equipped on the fuel injector tester, but the new original pump on the test bench which are bought by foreign customers , because for foreign customers, it is not easy to do the after-sales service, in order to avoid future problems, usually use new genuine fuel pump, for China domestic customers, they prefer the cheap common rail test bench, and easy for after-sales service, so it is usually equipped with second-hand pump, that is, removed from the engine, but the performance is still intact.

In addition to these important components, the quality of other hardware on the common rail tester needs to be noted. For example, inverters, the good brand is such as LG or Siemens. Lower level is that made in Taiwan or China mainland, the cost is a little cheaper, like therail combination I talked about above, it can meet the test basic needs, but who know after 5-10 years?

There are other factors.

4.The flow sensor is the main core component of the common rail tester. The pulse is hundreds to more than ten thousands. The larger the pulse, the more accurate the precision and the quality, the price will vary greatly (without the sensor, the test bench is a scrap iron, one customer said). that the accuracy of the sensor directly determines the accuracy of the tested fuel. Some common rail test bench manufacturers use high-precision gear flow meters produced in Germany. Some manufacturers use Australian flow sensors. Some manufacturers use OEM China flow sensor. The flow sensor is produced in China, but the it shows the original name. In general, the German flow meter is the most expensive and the best quality.

5.Fuel circuit layout and fuel temperature control system are also very important. The test bench producer in China mainly use two types temperature controlling system, air-conditioning refrigeration and air-cooling. The air-cooled system is relatively simple, and there is no problem of after-sales service. However, the temperature control of air conditioning and refrigeration can control the temperature more well

6.The selection of electronic original devices also affects the service life of the common rail test bench. These small components can only be seen by the customer to see its quality. If the quality of the electronic components are not good, the test bench will have some minor problems, although they are not big, but they will make you feel bad.

7.The software control system of the common rail test bench. After more than 10 years of development, there are only 2-3 software producer in China to supply circuit board to all these test bench manufacturers, that is, it is possible that many test bench manufacturers use the same software system, just These programmers have designed different appearances for different test bnech manufacturers, avoiding the embarrassment that customers have identified as “plagiarism.” These programs are slightly different, each with its own advantages, customers can choose the style they like. If there is a problem with the test bed software, the after-sales solution is usually to replace the board directly.

8.Finally, user-friendly design and a better user experience of the common rail tester are also important.

9. Hoping my above ideas can be helpful for you to choose the common rail test bench that you are satisfied with.

good article, it is helpful, thanks,