Common Rail Injector Tester-Stroke Measuring Tool ( Applys For Bosch CRI and Denso injectors)

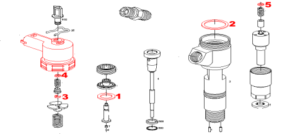

Bosch CRI common rail diesel injector test- stroke measuing tool:

1:Armature lift adjusting shim

2:Remaining air gap adjusting shim

3:The armature total range adjusting circlip

4:Solenoid valve spring force adjusting shim

5:Nozzle spring force adjusting shims

- Armature lift of the CRI diesel injector (standard value:45-45um)

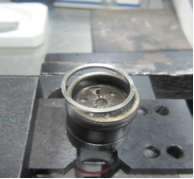

Remove solenoid valve, remove solenoid valve springs, shims, remaining air gap shims, put a small bush with openings into, screw the pressure cap with opening and screw it down according to <stand torque>, fit on adaptor and amesdial, make sure amesdial slide well and shows zero, gently press the top of the meter axis with fingers, repeatedly press a few times to ensure accurate accuracy, what it display now is: Armature lift.

- The armature total stroke test data of the CRI diesel injector: (Standard values: 55-70um)

Remove the small circlip, remove the armature plate, spring, using special tool to dismantle valve assembly pressure cap, remove the armature assembly, ball valve and ball valve base, fit on the armature assembly and lift shims, screw down valve assembly pressure cap according to <stand torque>, fit on the armature plate, spring and circlip in order. Fit on a thick shim, and put the bush with opening into, screw the pressure cap with opening and screw it down according to <stand torque>, fit on adaptor and amesdial, make sure amesdial slide well and show zero, gently press the top of the meter axis with fingers, repeatedly press a few times to ensure accurate accuracy, what it display now is: The armature total range.

3.Remaining air gap tester data of the diesel injector : (standard value: 35–55um)

Remove the solenoid valve of CRI diesel injector, put into remaining air gap shim, choose proper gauge stand adaptor and measuring pin, make amesdial show zero on flat surface.

3.1 Now test the distance between armature plate and remaining air gap, to test again after changing the angle to make sure accuracy, and make a record for the data.

3.2 Test the distance between remaining air gap and electromagnet, to make adaptor surface close together with solenoid valve end face when testing.

Use the data to subtract the data tested by first step is remaining air gap.

DENSO common rail diesel injector stroke test data

Armature stroke test data: (standard value: 45-55um)

- Dismantle solenoid valve of denso injectors, choose adaptor, flat headmeasuring pin and amesdial, and make the amesdial show zero on flat surface, put the armature liftshim on the injector, make amesdial back and forth rotation to ensure the stability test, make a record for the data.

2.Choose standard adaptor and make it show zero on flat surface, make the gauge stand adaptor surface close togetherinthe end face of the solenoid valves on the solenoid valve, put meausring pin in from gap of solenoid valve side to the bottom and to test several points to make sure testing accuracy, and make a record for the data. Use this data subtract the data in step 1 is armature lift.

Common rail injector test steps and the impact to the diesel engine’s performance.

LEAK TEST: This test verifies that leakage of valve assembly, high pressure sealing ring, nozzle pin valve pressure cap part.

VL: Max injection amount: too large injection will bring smoke and large fuel consumption; too small injection amount will make the vehicle powerless and slow to speedup. The tolerance each common rail diesel injector should be controlled within 6mm3/HH when adjusting, which is mainly adjusted through nozzle prcision shims.

TL/EM: medium speed / emission point fuel injection amount, fuel injection characteristics verification point, excessive injection will bring smoke and emission exceed the standard; too small injection will make the vehicle powerless and slow to speedup. This is decided by nozzle spring shims, armature stroke, cross stroke adjusting shims and solenoid valve spring force shims.

LL idle fuel amount: excessive idle will bring smoke, too small will lost throttle and flameout, start-up difficulties, fuel amount unevenness will lead rotation speed do not stabilize, noise, and the engine swings during speedup. Unevenness should be controlled within 2mm3/HH, which is mainly adjusted by nozzle spring force shims.

VE pre-injection fuel amount: too large the fuel will knock cylinder and bring smoke, too small will make large noise of the engin, start-up difficulties and powerless to speedup. Unevenness should be controlled within 0.5mm3/HH, which is mainly adjusted by solenoid valve spring force shims.

Remarks: The premise of the above adjustment method is various range adjusted within its scope.

Leave a Reply

Want to join the discussion?Feel free to contribute!