Description

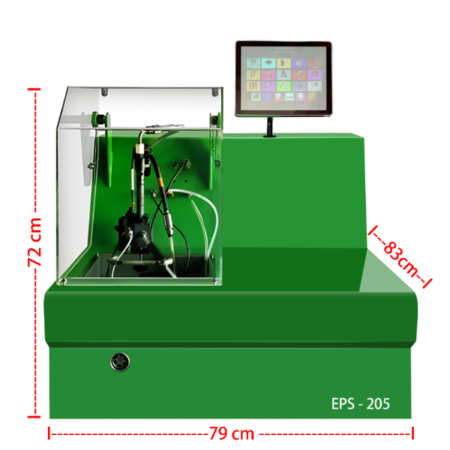

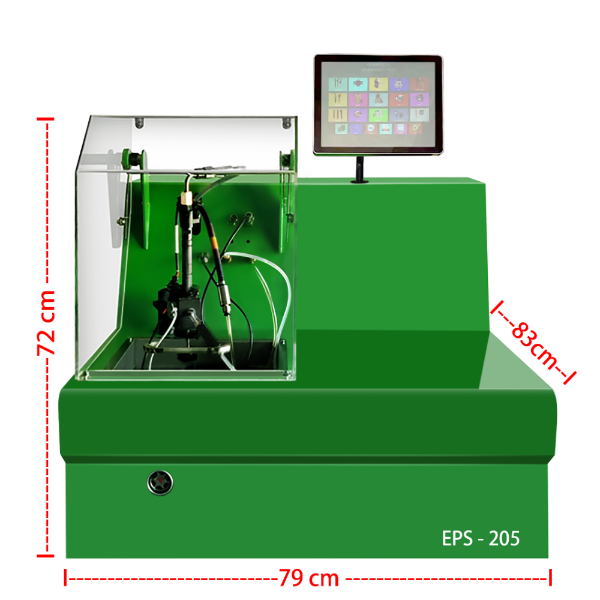

Technical parameter of the injector calibration machine:

- Output power: 2.6KW

- Rotation speed controlling: inverter

- Power supply: 220V 50/60HZ

- Fuel tank: 8 liters

- Fuel temperature controlling : 40±2℃

- Filtration: less than 5μm

- Machine size: 700×600×670 mm

- Weight: 110kg

- Flow sensor of the injector tester: imported flow sensor

This diesel injector test equipment software advantage:

- Industrial computer real-time control, Windows operating system, built-in display, touch screen operation.

- Real-time display of fuel injection and back-flow curve, automatically tests the fuel quantity of all working conditions, and generates report after testing.

- Correct the compensation value setting in the software, to revise the tolerance of the flow sensor, ensure the flow consistency in each step and each machine.

- Intelligent algorithm is used on this injector tester machine, to automatically calibrate the fuel quantity of the new injector, and generate test plan after calibration.

- Parameter customize : rail pressure, pulse width, and fuel injection time when using this diesel fuel injector tester.

- Testing data same as Bosch, Denso, Delphi original data, accuracy can reach the original level

Common rail injector test bench hardware configuration:

- Equipped with Bosch genuine CP3 pump, which can drive various solenoid valve common rail injectors and piezoelectric CRDI injectors.

- Frequency inverter equipped to achieve testing function under different speed conditions.

- The filter is used before fuel comes to flow sensor, can effectively keep the sensor clean and extend the flow sensor usage life.

- Accurately distinguish the injectors’ defaults , for example, missing cylinders, knock cylinders, or speed limiters when the injector working on the engine.

- Testing diesel fuel can be heating or cooling automatically.

- The common rail injector tester has the short-circuit protection, ground protection, over pressure protection during the testing.